-

Motorsport

-

AeroSpace

-

Engineering

-

Products/Services

-

Automotive Engineering

-

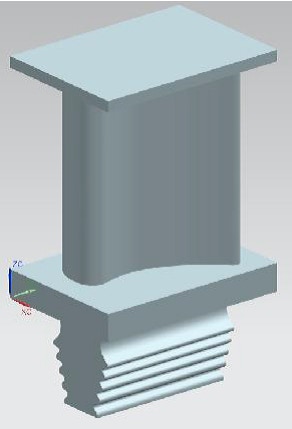

Race Gearboxes Design, Production, Testing and Revision

-

2WD 4WD Racing Gearboxes

-

Hybrid Powertrains Design, Production and Testing

-

Nanotechnology Lubricants

-

Custom gearset

-

Racing limited slip differentials

-

Custom Ring and Pinions

-

Composites parts design and manufaturing

-

Gender equality plan

-

-

Cars on sale

-

Press Room